Customers Include:

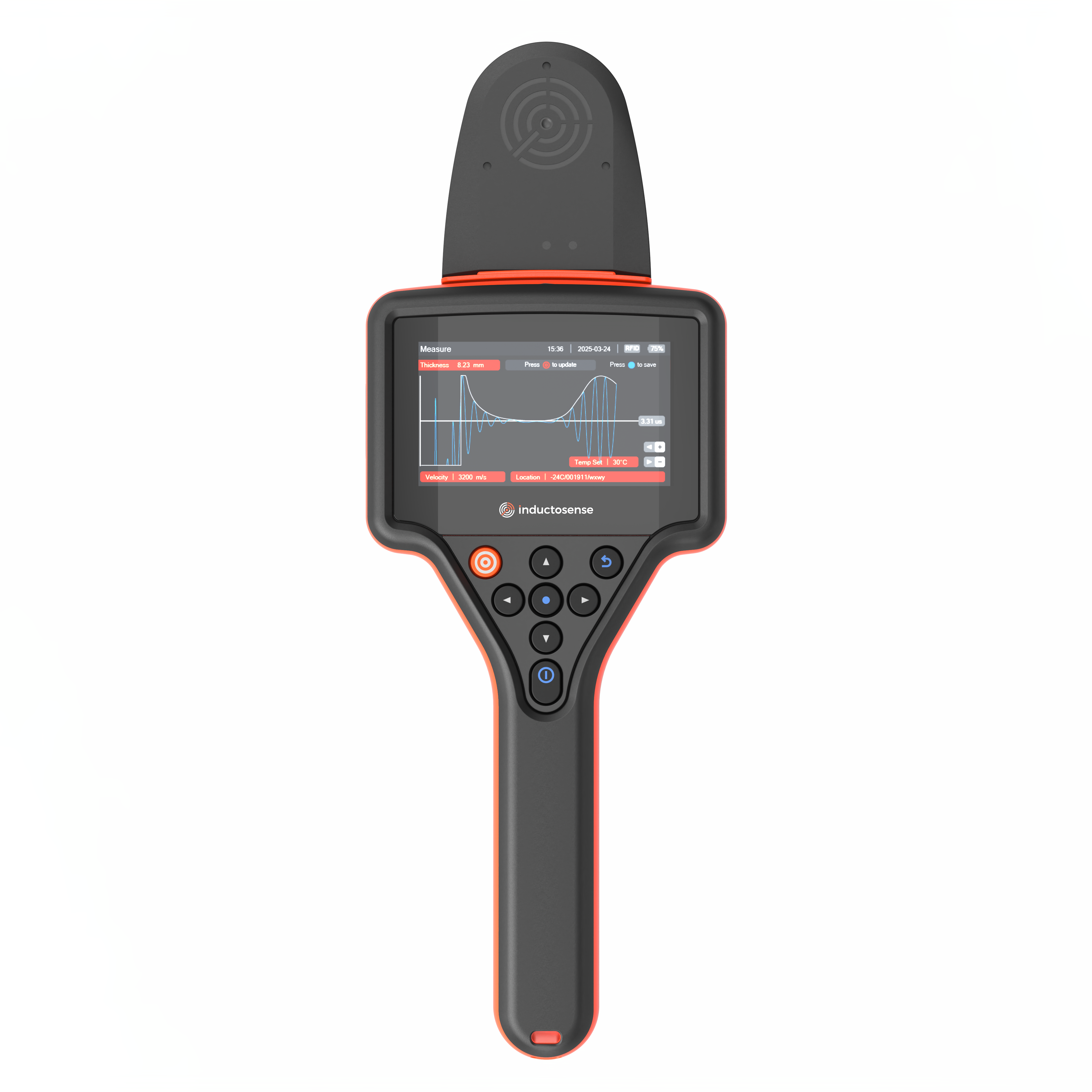

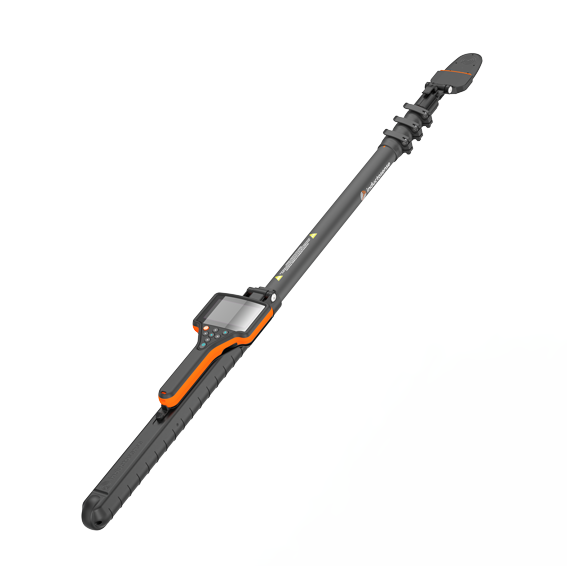

Featured Products

Industries We Work With

The WAND Solution is currently deployed across a range of industries including oil and gas, chemical, mining, renewables and nuclear. Inductosense are also working with original equipment manufacturers to integrate the WAND technology into products.

Contact Us

Contact Inductosense today to learn how WAND can upgrade your manual UT inspection to fully digitalised wall thickness monitoring.

Enter your details below

"*" indicates required fields